Data Acquisition System (DAQ)

My most significant project on ESRA was designing, building, testing, and calibrating the data acquisition system (DAQ) for the static fires. The system needed to gather pressure, thrust, and temperature data.

The full-scale test stand worked similar to the sub-scale test stand only with a larger adapter to transfer the thrust to the load cell without blocking the copper tube to the pressure transducer.

Transducers

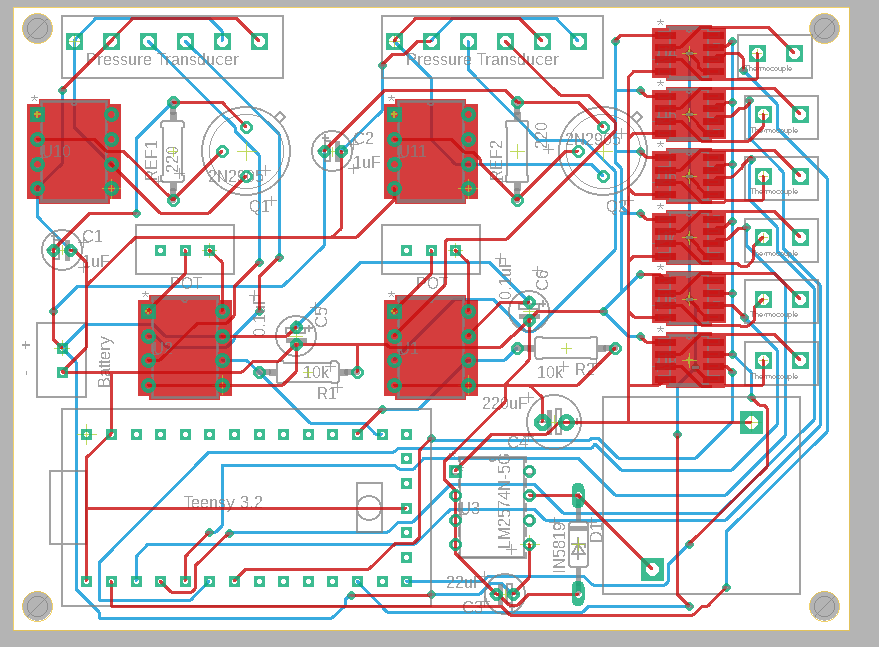

The pressure transducer and load cells both output 2mV of differential signal per volt of excitation. I used a 10V reference and a differential amplifier with a gain of 165. The circuit diagram below shows a schematic of one of the channels.

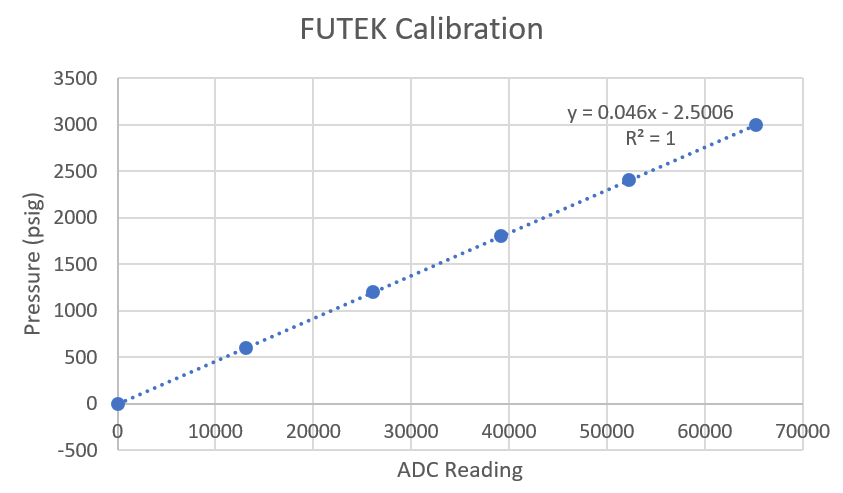

Calibration

I calibrated the load-cell using the school’s Instron material testing machine. I found it was easiest to calibrate it to the amplified signal to remove any gain error from the amplifier.

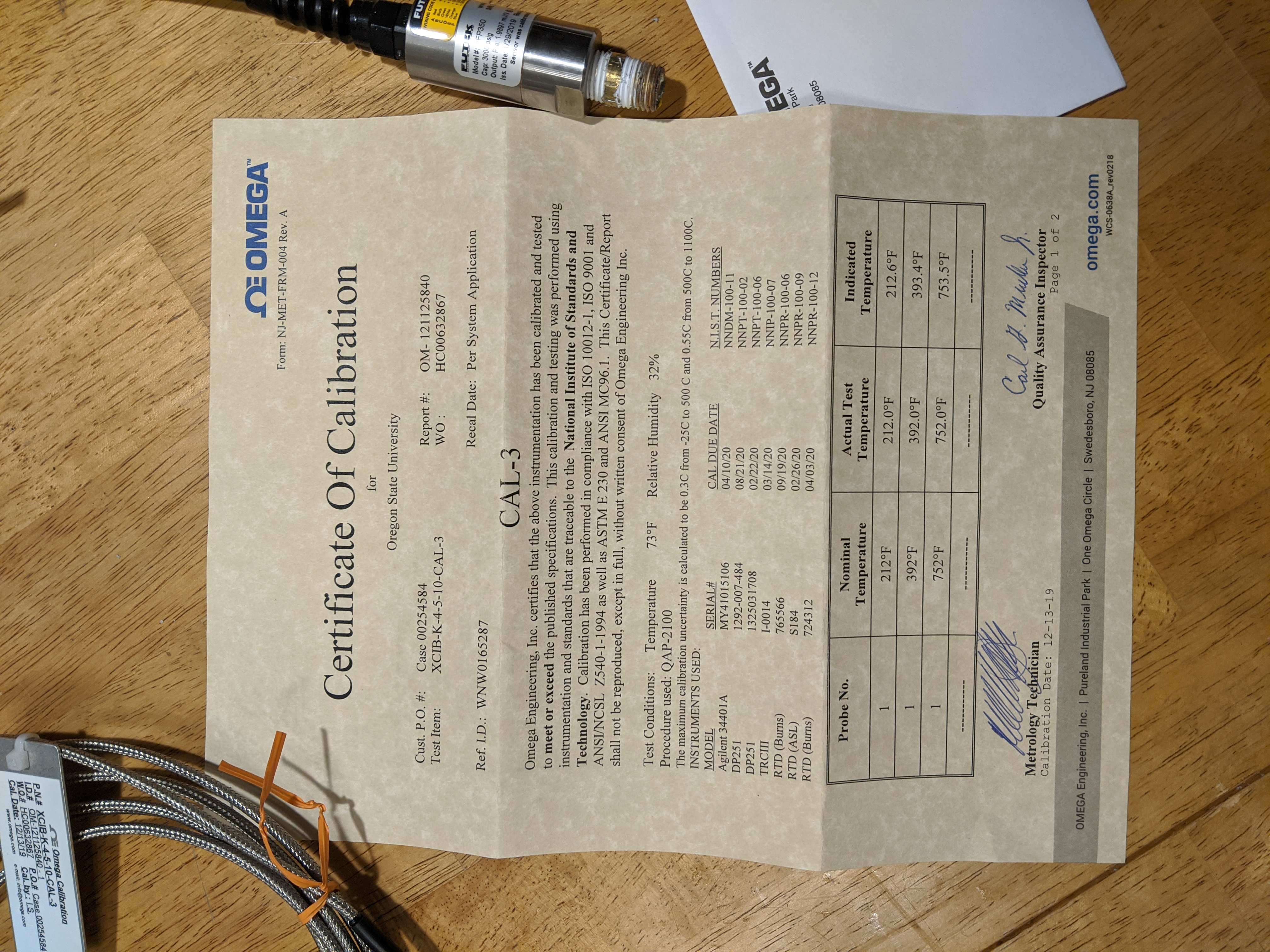

The pressure transducer came with a calibration sheet from the manufacturer. This was very fortunate because we did not have the equipment to calibrate pressure transducers in house.

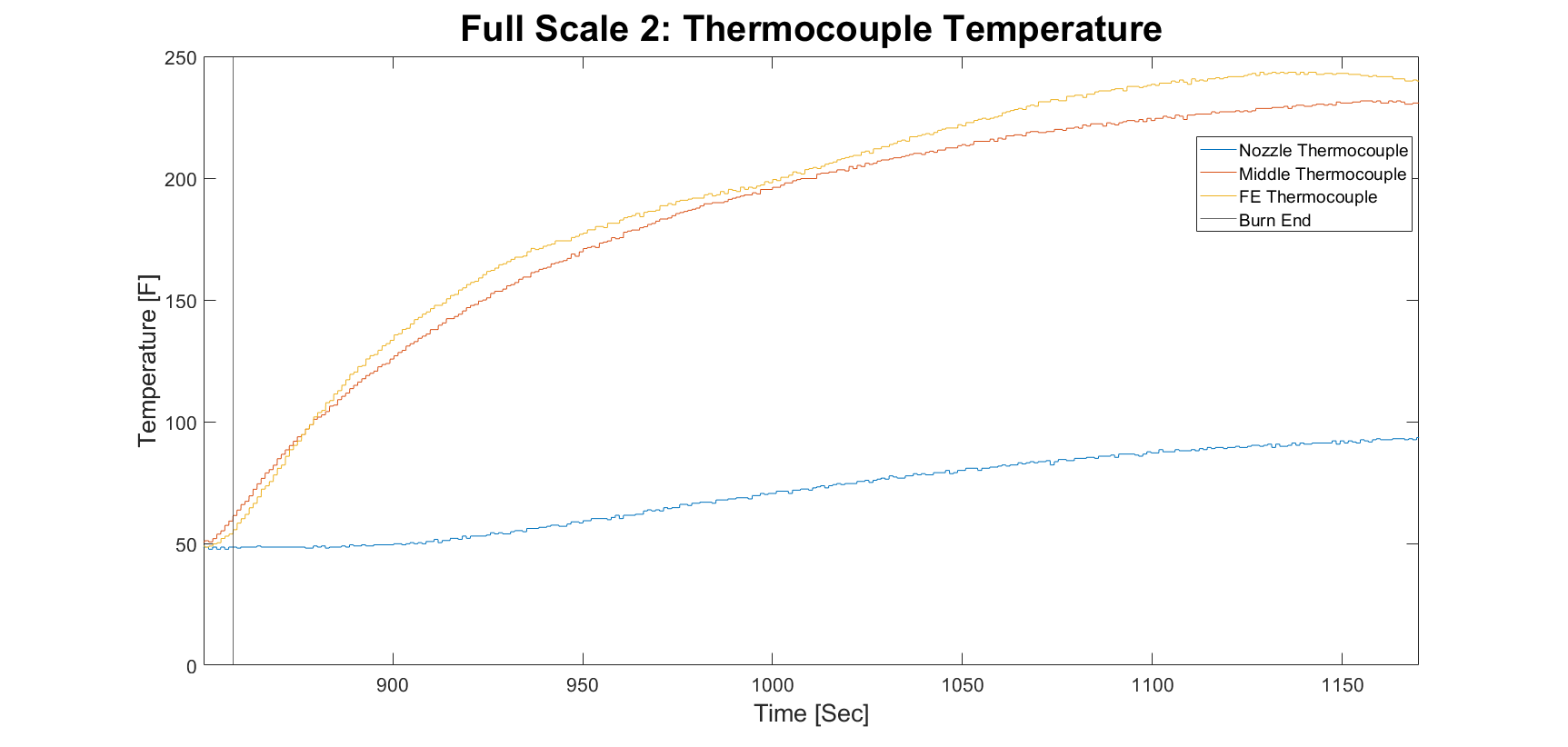

Thermocouples

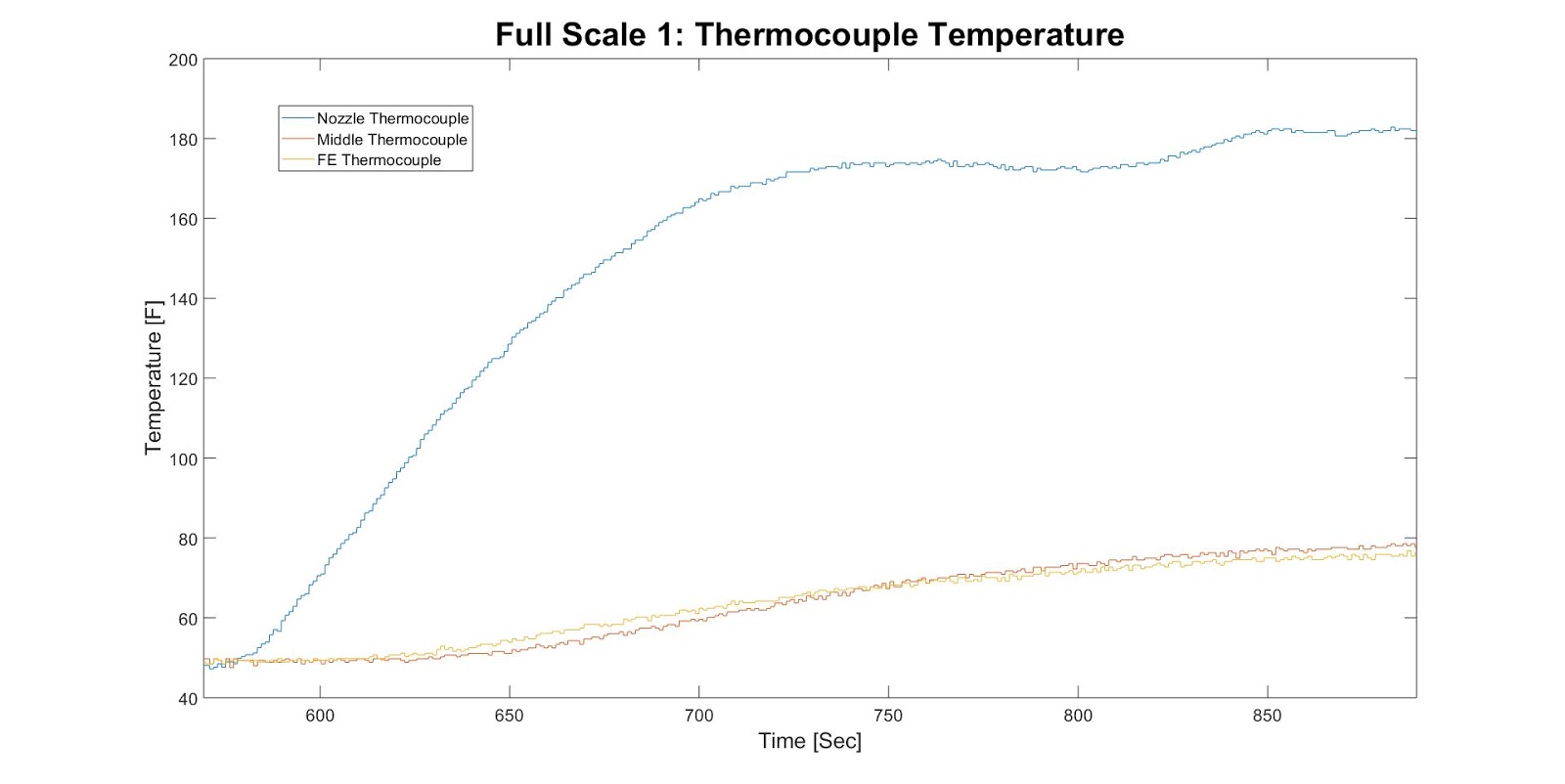

OSU AIAA did not have any thermocouples on hand, so I initiated an $1,100 sponsorship with OMEGA Engineering for six high-end K type thermocouples with a calibration. The sponsorship letter I wrote can be found here!

To collect the thermal data, I used a K type thermocouple to digital converter chip (MAX6675) to communicate with the microcontroller over SPI. The DAQ supported up to six channels. We attached the thermocouples to the motor tube using hose clamps and thermocouple putty to lower the thermal contact resistance.

ADC and Data Logging

I used a Teensy 3.2 for the DAQ because it had 16-bit ADC and ran at 72 MHz which was fast enough for our application. I connected a laptop to the microcontroller over USB and saved the data to a CSV file using Putty.

Hardware

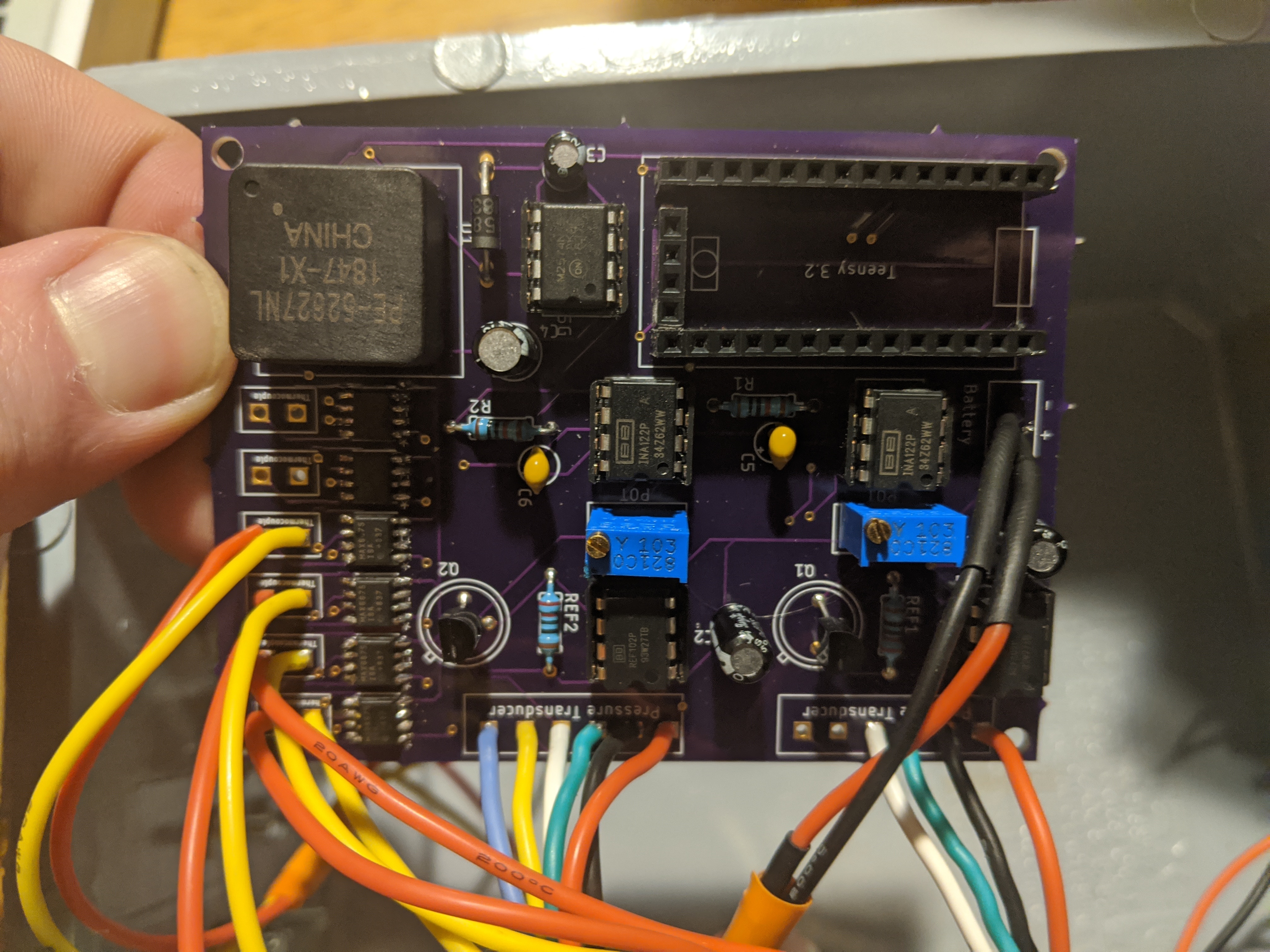

I created a PCB for the DAQ in Eagle and got it printed from OSH Park.

After populating the board, I mounted it inside of a sealed PCV junction box using standoffs.

I used Deutch connectors because they are sealed and can be disconnected and reconnected quickly.

Results

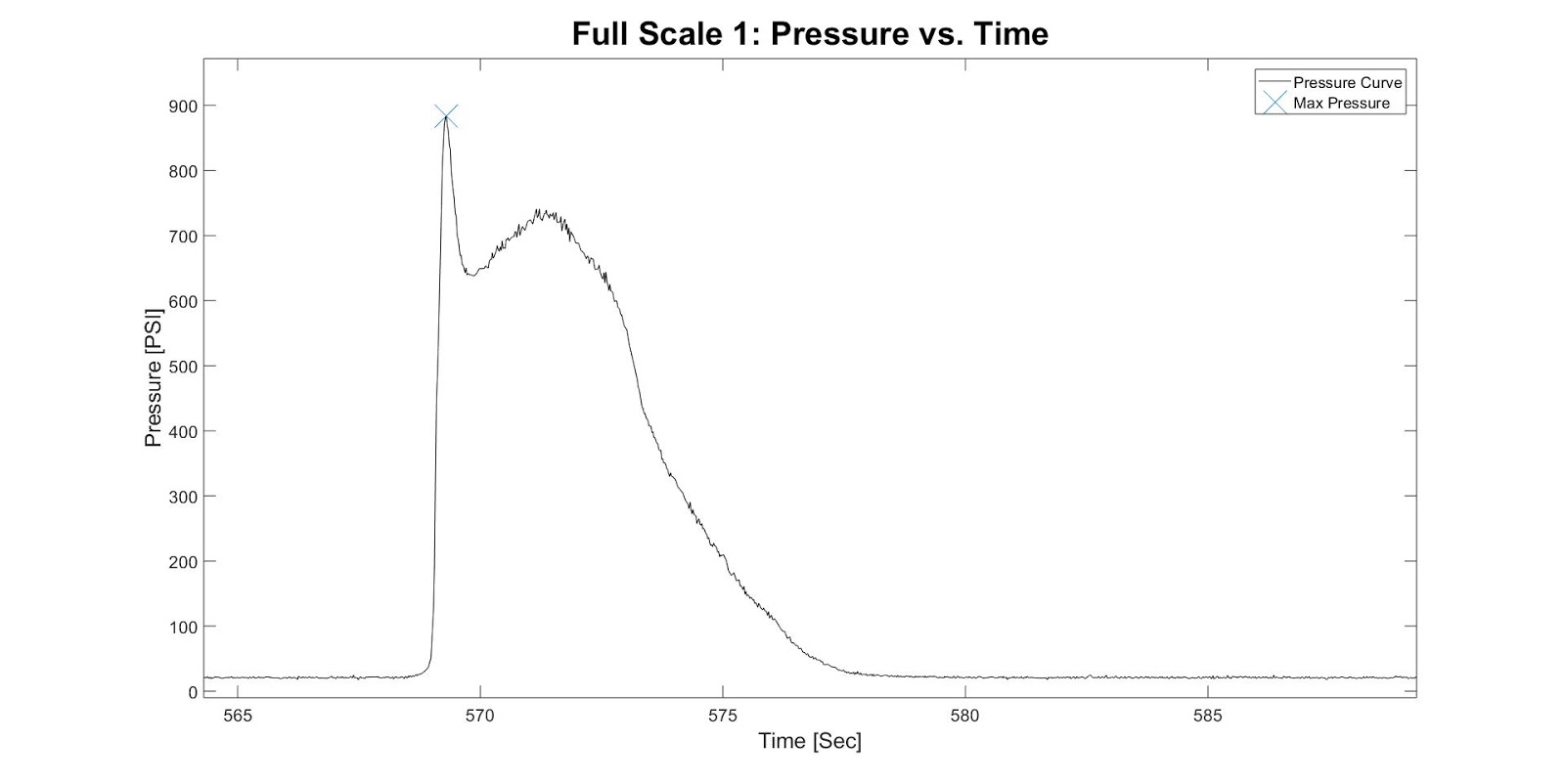

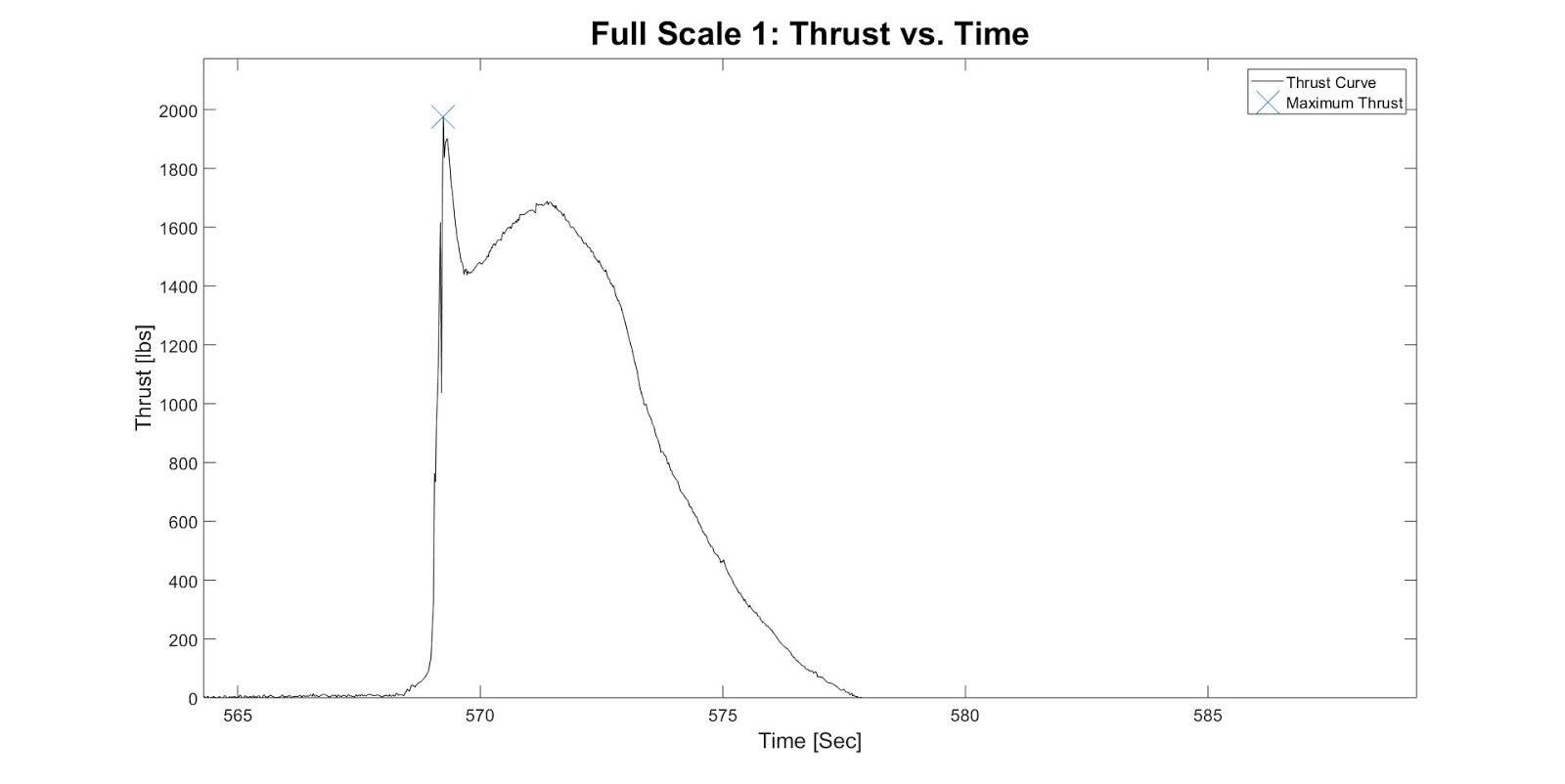

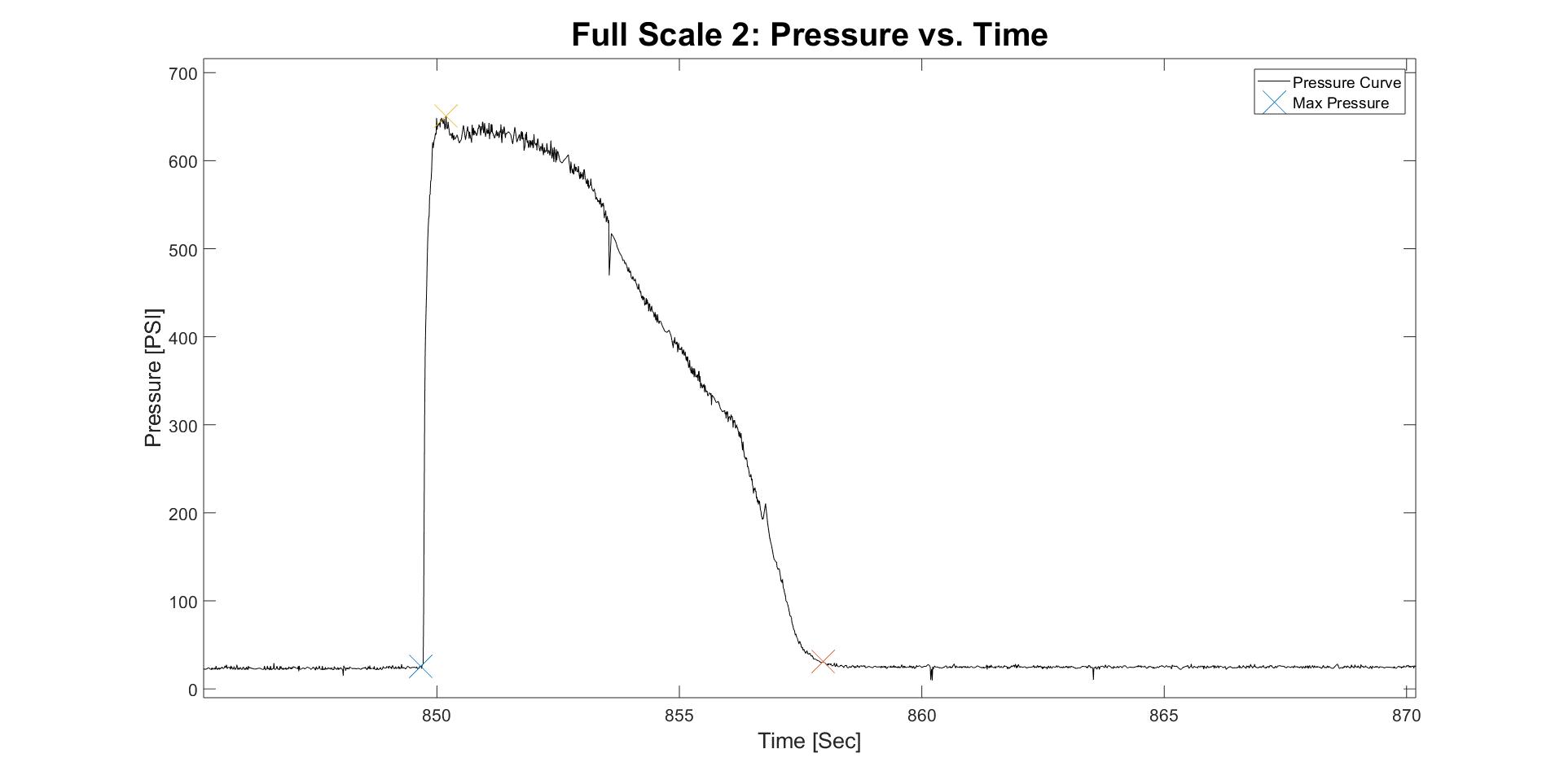

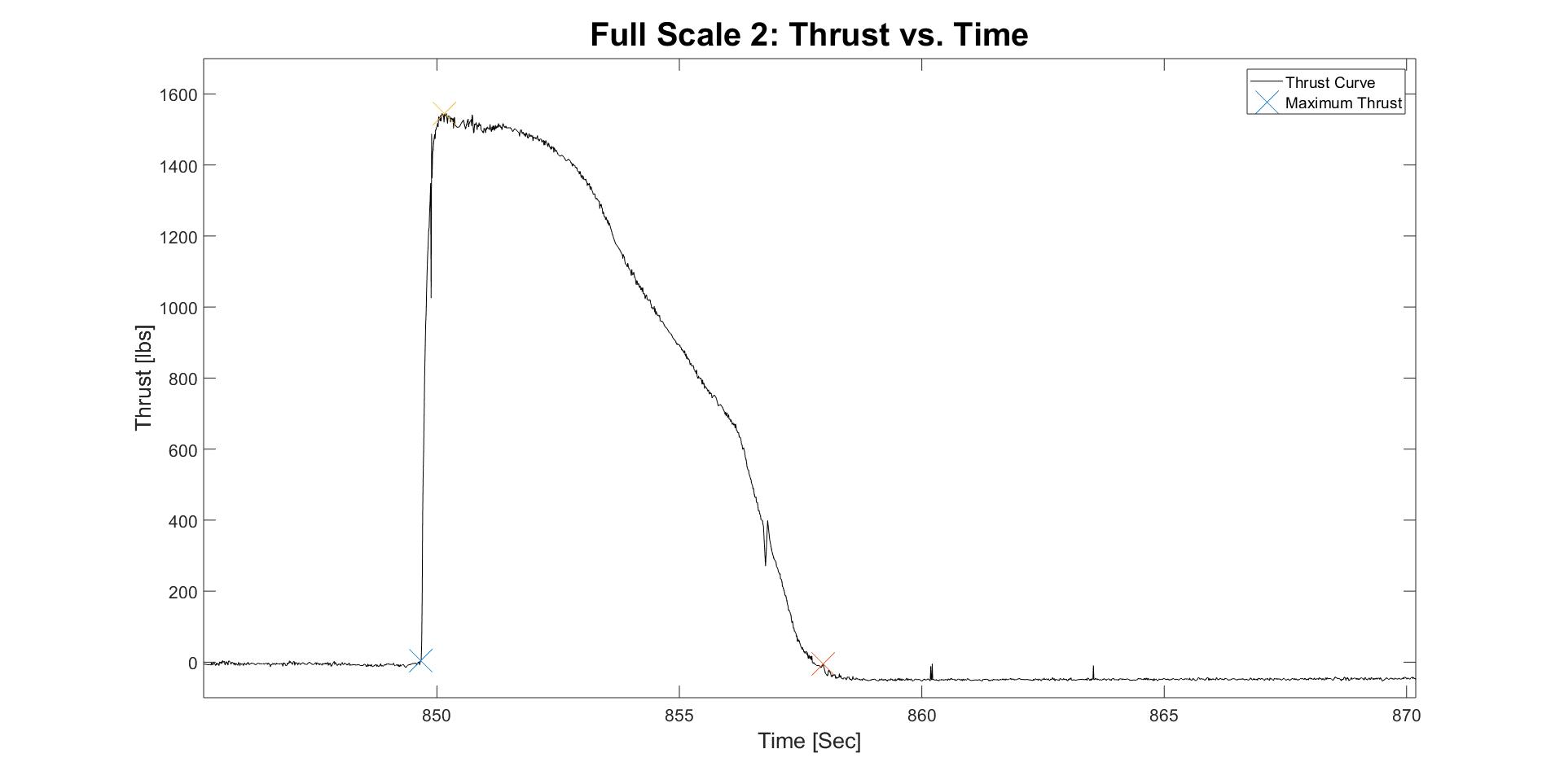

This project was on a very quick timeline. We used it to collect sub-scale data starting in Week 7 of Fall term, which included pressure and thrust data. It then also needed to be ready to collect temperature data by Week 1 of Winter term. It was a push to get things ready in time with other ESRA responsibilities as well, but I am proud of the data we were able to collect from it. It was the first year ESRA has had good data, which was crucial for accurately characterizing the propellant, validating that the full-scale motor was safe from over-pressurization and thermal failure, and accurately generating a thrust curve to predicting the rocket’s altitude.

Other AIAA teams like the High Altitude Rocketry Team (HART) competition team and the research vacuum casting team also relied on the DAQ throughout the year to collect static fire data for their projects.

First full-scale static fire

Second full-scale static fire

Documentation

The DAQ was designed to be used not only by our team, but also by other OSU AIAA teams and future years as well. I wrote a DAQ manual so that other people would know how to use it. If you are interested, it can be found here here!